- +91-9833300056

- sales@numaticpumps.com

- Mumbai, Maharashtra, INDIA

Industrial Pumps

Numatic Pumps is a true “Made in India” company that proudly manufactures and assembles all of its pumps in India Mumbai. After all, finding solutions to various issues is far easier when all relevant personnel is under the same roof. Similarly, staff proximity allows us to iterate on existing designs quickly, allowing us to create custom products for clients with our machine shop and moulding shop working in tandem. And our employees have the drive, expertise, and experience to turn your vision into a reality. These engineers provide both design services and ongoing support, indicating that they are knowledgeable about both pump theory and practical application. We have a wide range of pumps available, including centrifugal, self-priming, air motor, submersible, and more. By clicking the buttons below, you can view pumps within a specific series, filter by pump type, or enter your part/model number to view more information about that product. Still can’t find what you’re looking for? Please contact us if you require any further assistance.

Numatic Pumps is the brand with the greatest technical expertise in Manufacturing Industrial Pumps Mainly a Magnetic Drive Pumps which is a Sealless Pumps. The other Range of Pumps in Magnetic Drive Pumps is PP Magnetic Drive Pumps, PVDF Magnetic Drive Pumps, PTFE Magnetic Drive Pumps, and SS Magnetic Drive Pumps. Which are also called Plastic Pumps Chemical Pumps or Acid Pumps. The company also offers excellent service in addition to maintenance and repairs for Industrial Pumps. Also includes the supply and installation of the Pump’s Mechanical spare parts. The Centrepiece of the Numatic pump product portfolio is the PP – PVDF – PTFE Magnetic Drive Pump also called Mag Drive Pump. Other Types include for example PP – PVDF – PTFE – PFA Monoblock Pump & PP – PVDF – PTFE – PFA Centrifugal Coupled Pumps, Motorised Barrel Pumps, Motorised Screw Barrel Pumps, Pneumatic Barrel Pumps, Pneumatic Screw Barrel Pump, AODD Pump, Air Operated Double Diaphragm Pump, Vertical Sealless Pump, Dairy and Pharma Pump, and more such Industrial Pumps.

Magnetic Drive Pump

Magnetic Drive Pump Designs have become the standard for applications requiring High Acidic and Corrosion Resistant. Magnetic Drive Pumps are Sealless Pumps used for Acids, Alkalis, Corrosive & Hazardous Chemical, Electroplating and Pharmaceutical Industries. “Magnetic Coupled” refers to the coupling between the wet end of the pump and the motor. In “direct drive” the impeller of the pump is attached to the shaft of the motor and this design depends on the Mechanical shaft seal. In a magnetic drive pump, the wet end and motor are two separate parts, connected by a motor bracket. At the end of the motor shaft, a drive magnet is attached, and as it rotates around the rear housing, the impeller, which is fixed upon another magnet, spins in synchronization. Our magnetic drive pump designs offer a wide range of capabilities from compact NP-15 configurations up to 800 Liter per Minute large chemical process pump series in Polypropylene, PVDF and SS 316.

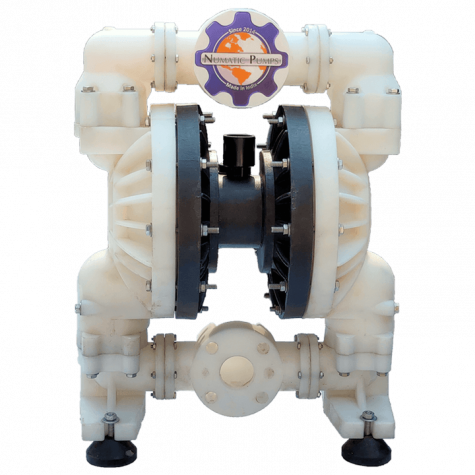

AODD Pumps

AODD pumps, also known as air operated double diaphragm pumps or pneumatically operated diaphragm pumps are used in a variety of mining, paint, acid, chemicals applications and can handle a wide range of feeds such as sludges, slurries, abrasive and sensitive fluids. They are especially useful where electricity is unavailable or in explosive or flammable areas because they are powered solely by compressed air. AOD pumps are a type of reciprocating diaphragm pump or positive displacement pump that uses compressed air to move two diaphragms. It is made up of two pumping chambers that are filled and discharged alternately by the movement of flexible diaphragms. To generate the pumping action, compressed air is alternately fed into and vented from air chambers on opposite sides of the diaphragms. The air section, which includes a shuttle valve, alternately applies air to the two diaphragms which are equipped with a set of a check or ball valves.

Authorised Dealer of

Available MOC

SS - Polypropylene - PVDF

Basically, mono means single, as its name suggests, Monoblock Pump means the Pump unit is rigidly connected to a Motor, Motor and Pump are built together as a Single Unit in the same housing, in which a common shaft contains the rotating parts.

Available MOC

SS - PP - PVDF - PFA

Centrifugal coupled pumps are standalone units comprising a bare pump and an electric motor mounted on a common base frame. The separation between them prevents heat transfer from the pump to the motor, preventing it from major damage from excess heating.

Available MOC

PP - PVDF

Magnetic drive pumps utilise magnets to connect the motor to the pump via a magnetic coupling, thereby eliminating the need for a direct shaft. These Magnetic Drive Pumps are often used where leakage of fluid poses a great risk, such as in hazardous and flammable liquids.

Available MOC

SS - Polypropylene

The term Self Priming Pump describes a Centrifugal Pump that uses an air-water mixture to reach a fully-primed pumping condition. A Self-Priming Pump clears its passages of air and start pumping. The Self Priming Pump is designed to lift water from some level below the pump suction without having to fill the suction piping with liquid. It creats a partial vacuum at the Pump suction which removes the air from the suction line.

Available MOC

SS 316

Dairy pumps are specially designed pumps used in milk processing, dairy plants, and food & beverage industries. They ensure safe, hygienic, and efficient transfer of milk and other dairy products without contamination.

Hygienic Design: Made from SS 316 / SS 316L stainless steel with smooth surfaces to prevent bacterial growth.

Easy Maintenance: Simple disassembly for cleaning and inspection.

Available MOC

SS - PP - PVDF - Aluminium

Air Operated Double Diaphragm Pump is a positive displacement Pump that uses compressed air as a power source and diaphragms to pump fluid. When compressed air is passed through an AODD Pumps the air is shifted from one chamber to another by a linked shaft that allows the chambers to move simultaneously back-and-forth this motion forces liquid out and fills another chamber at the same time.

Our range of Material

Some of Our Prestigious Clients